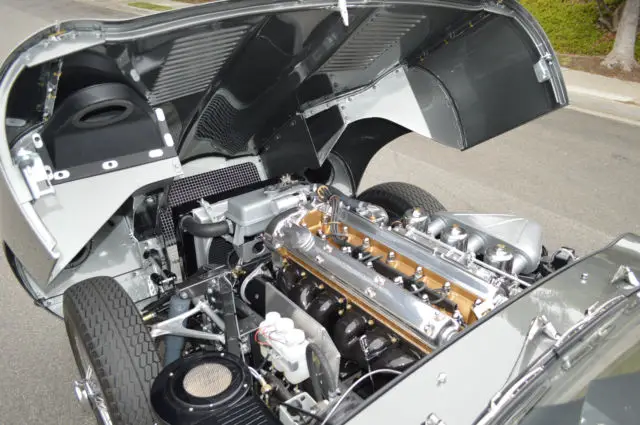

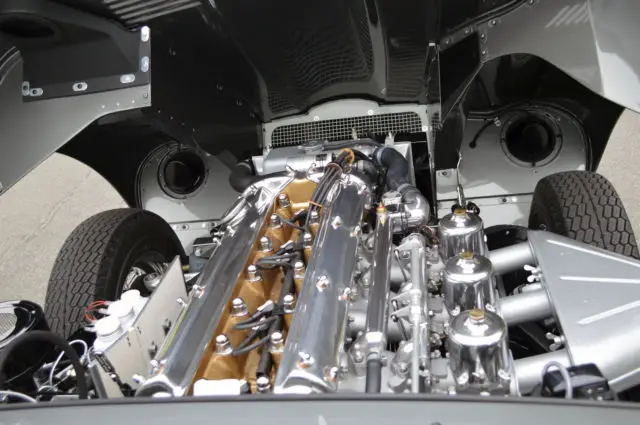

| Classic Showcase is pleased to present this striking 1964 Jaguar E-Type for your consideration. This XKE has been rotisserie-restored with the utmost of attention taken to detail. It has received a new finish of Gunmetal Grey, and is complimented with a perfectly fit Red interior in all the proper correct materials by master trimmers in our upholstery department. Our craftsman paid strict attention to the fit and finish of all the upholstery in the Roadster, as well as the convertible top bows being restored and a new top and boot were precisely fit. All the XKE's mechanical components were gone through or replaced and setup to their respective factory specifications, such as: the engine block and head, transmission, rear end assembly, and all of the vital systems such as: the electrical, cooling, fuel, and the hydraulics. The engine's accessories were rebuilt as well, including: carburetors, starter, generator, with everything else under the bonnet and throughout the car either restored, replaced, as is it seen today. After the engine, transmission and components were built, it is placed on our test station for setup to be fine-tuned. We perform this task over several days of cold to hot running for optimal performance and setup to ensure the dependability before it is installed in the car. The E-Type was dissembled, and all parts were fully documented, photographed and inspected. The vehicle body was placed on a rotisserie for the body work, and metal finish and leaded. All body parts, britework, and rubber were fitted to the car in bare metal. After that process, we removed the body parts, britework and rubber to prepare the car for paint. We then applied primer, sealer, base coat, and clear coat. All parts were individually painted off the car in the booth. Finally, a few days later after it cured, we color sanded and buffed the E-Type to the beautiful finish you see before you today. With the body and paint process now completed, the vehicle and its associated restored and new parts enter the Assembly Area, where our experienced team of craftsmen start the assembly process in a designated area. This area is surrounded by the restored and new parts that will be assembled on to this vehicle. All the following restored and new parts (plus others) were installed on the XKE: EXTERIOR: new windshield, door glass, windshield wiper arms and blades, front parking light lenses and rear brake light lenses, reverse light lens, license plate light assembly, motif badge and bracketry, chrome screws for headlight rings, all britework on the outside and inside of the Jaguar has been restored to a high level, then re-assembled onto the car, new tires, chrome wire wheels, and knock-offs, plus much more. INTERIOR: horn button, all new dash excusions and knobs, dash top, speaker grilles, glove box, seat belts, emblems, gear shift knob, chrome bezel around shifter, rubber floor mats (over carpet), restoration of original steering wheel, installing new turn signal assembly, window mechanisms and door regulators restored and installed with proper hardware and shims, restored grab handle and under dash panels installed with all proper hardware and fasteners, etc. UNDER THE BONNET: everything on the inside and the outside of the bonnet has been restored back to its original condition; a new Battery along with its proper cables, hardware bracketry and decal was installed. Then, a new aluminum radiator, header tank with hoses and clamps, radiator cap, thermostat, porcelain exhaust manifolds, heater valve, all electrical relays and systems, a restored heating system, water pipe replacement in the firewall, as well as all rubber, grommets, seals and hardware and more. IN THE BOOT: An epoxy-sealed gas tank was fully restored, painted, and installed. Then, a new fuel pump was installed back into the gas tank with the proper gasket and all its related accessories and hardware. In addition, an electrical junction box with the proper plaque located on the boot's bulkhead was added. UNDERCARRIAGE: The steering rack assembly was restored, as was the suspension, CAD plated, and new bushings installed, as well as ball joints and tie rod ends, etc. The driveshaft was restored with new U-joints, and new shock absorbers were installed with bushings. Then, a new stainless-steel exhaust system was hung with its proper clamps and hardware along with show-quality resignator tips. AFTER ASSEMBLY: Once the assembly process of the E-Type is completed, we align the front and rear end before its first test drive. The Master Technician then performs a number of test drives over several days, and adjusts the Roadster making sure it is torqued to proper specifications. After each test drive, the vehicle is elevated on a lift, enabling further inspections of the undercarriage, under the bonnet, and the integrity of the entire vehicle. By analyzing the results of each test drive, the Master Technician can then assure the entire vehicle is operating and functioning as optimally as it can in all driving scenarios. Our management team then drives the E-Type a number times over several days to check and verify that all systems and operations are achieving perfection. During these days of driving, we will put approximately 100 miles on the car before making it available. |